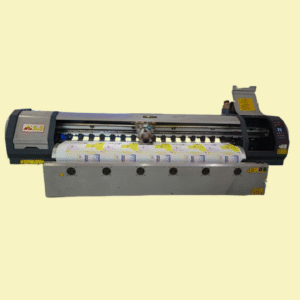

Plotter Machine-Sublitech

₹ 35,999 Original price was: ₹ 35,999.₹ 25,999Current price is: ₹ 25,999.

Key Components & Structure

Here are typical components you’d find in a Sublitech plotter (or similar plotter machines):

| Component | Function / Description |

|---|---|

| Frame & Body | A rigid structure to hold moving parts stable, reduce vibrations, and ensure accuracy. Usually made from aluminum or steel. |

| Drive System / Motors | Stepper motors or servo motors that move the cutting head (and sometimes material feed) precisely along X, Y (and sometimes Z) axes. |

| Cutting Head / Tool Holder | The mount for blades, pens, or cutting tools. In some systems, it may also house sensors or cameras (for alignment). |

| Blade / Cutting Tool | The actual cutter (knife, drag blade, tangential blade, or oscillating blade) that slices through material. The blade type depends on material thickness and flexibility. |

| Material Feeding / Rollers | Rollers (pinch rollers, pinch wheels) engage and guide the material (vinyl roll, heat transfer vinyl, etc.), ensuring smooth feed and alignment. |

| Control Interface / Panel | Buttons, LCD or touchscreen interface to control speed, pressure, and to manage jobs. |

| Computer / RIP / Controller Board | Electronics and software that orchestrate movements, interpret design files (e.g. HP-GL, PLT), and coordinate cutting. |

| Sensors / Registration / Alignment Systems | To detect edges, marks, or registration lines on printed materials so that the cutter aligns exactly with printed graphics. |

| Safety / Housing | Covers, limit switches, emergency stop, and protective elements to ensure operator safety and avoid damage. |

Description

A Plotter Machine (Sublitech / for sublimation and vinyl / printing context) is a controlled, precision machine designed to cut, plot, or transfer designs—often in conjunction with sublimation printing or other digital-print workflows. “Sublitech” suggests that this plotter is integrated or associated with a sublimation or textile / signage printing ecosystem (e.g. used to cut designs, masks, templates, decals that complement sublimation prints).

Such machines are common in the printing, signage, textile, advertising, and decoration industries. They help convert digital artwork into physical output with exacting precision.

Key Components & Structure

Here are typical components you’d find in a Sublitech plotter (or similar plotter machines):

| Component | Function / Description |

|---|---|

| Frame & Body | A rigid structure to hold moving parts stable, reduce vibrations, and ensure accuracy. Usually made from aluminum or steel. |

| Drive System / Motors | Stepper motors or servo motors that move the cutting head (and sometimes material feed) precisely along X, Y (and sometimes Z) axes. |

| Cutting Head / Tool Holder | The mount for blades, pens, or cutting tools. In some systems, it may also house sensors or cameras (for alignment). |

| Blade / Cutting Tool | The actual cutter (knife, drag blade, tangential blade, or oscillating blade) that slices through material. The blade type depends on material thickness and flexibility. |

| Material Feeding / Rollers | Rollers (pinch rollers, pinch wheels) engage and guide the material (vinyl roll, heat transfer vinyl, etc.), ensuring smooth feed and alignment. |

| Control Interface / Panel | Buttons, LCD or touchscreen interface to control speed, pressure, and to manage jobs. |

| Computer / RIP / Controller Board | Electronics and software that orchestrate movements, interpret design files (e.g. HP-GL, PLT), and coordinate cutting. |

| Sensors / Registration / Alignment Systems | To detect edges, marks, or registration lines on printed materials so that the cutter aligns exactly with printed graphics. |

| Safety / Housing | Covers, limit switches, emergency stop, and protective elements to ensure operator safety and avoid damage. |

Functional Capabilities & Features

Here are the functions and features a Sublitech plotter machine typically offers:

-

Precision Cutting: Ability to cut intricate shapes, curves, text, and fine detail with very high accuracy (tolerances often in fractions of a millimeter).

-

Variable Cutting Force / Pressure: The ability to adjust blade pressure based on material thickness or hardness (for example, from light paper to thick vinyl).

-

Variable Cutting Speed: To balance speed vs. quality depending on the complexity of the design.

-

Multiple Pass / Overcut: For cutting tougher or thicker materials, or for ensuring clean edges.

-

Support for Various Materials: Vinyl, heat transfer vinyl (HTV), adhesive films, paper, cardstock, masking films, textile films, etc.

-

Registration / Contour Cutting: Ability to read printed registration marks and cut precisely around printed designs (e.g. for stickers, labels).

-

Batch / Repeat Cutting: For production of multiple identical pieces (serial cuts).

-

Interfacing with Design Software / Formats: Compatible with common vector / design formats (e.g. AI, EPS, SVG, PLT, HP-GL) and standard plotting languages.

-

Integration with Sublimation Workflows: For example, cutting mask films, transfer sheets, or aligning with printed sublimation output.

-

Cost Management / RIP Features: Some specialized software (e.g. Sublitech’s “PowerPlotter” RIP) offers tools like color profiling, ink usage optimization, step & repeat, correction for stretching/shrinking in textile printing, etc.

-

Applications & Use-Cases

A Sublitech plotter machine is useful in many domains:

-

Textile Printing & Apparel: Cutting heat transfer vinyl, masking films, textile patterns, appliques.

-

Signage & Display: Cutting stickers, decals, vehicle wraps, window graphics, promotional banners.

-

Packaging & Prototyping: Cutting templates, packaging prototypes, dielines.

-

Craft & Decoration: Intricate artisanal cuts for home décor, custom decals, wall stickers.

-

Advertising & Branding: Logos, cutouts, signage overlays.

-

Industrial / Technical: Masking for printing, cutting industrial films or masking sheets.

Advantages & Benefits

-

High Precision & Quality: Cleaner edges, sharper cuts, less material waste.

-

Repeatability: Exact same output across many units — essential in production.

-

Flexibility: Able to switch jobs quickly, handle different designs & materials.

-

Time & Labor Efficiency: Automates cutting processes that would be tedious or error-prone manually.

-

Cost Savings Over Time: Less material waste, less human error, scalable production.

-

Enhanced Workflow Integration: With digital printing / sublimation, such plotters complement and complete the print-cut workflow.

Challenges & Considerations

-

Material Compatibility Limits: Very thick or rigid materials may exceed blade capability.

-

Maintenance & Blade Wear: Blades dull over time; rollers wear; calibration needed.

-

Alignment / Registration Accuracy: Especially for contour cutting over printed graphics, precise alignment is critical.

-

Software / Driver Support: Compatibility with design software, drivers, and updates is important.

-

Initial Cost & ROI: The upfront investment can be significant — must justify via production throughput.

-

Space & Environment: Needs stable power, level surface, ambient conditions (dust, temperature) matter.

-

Operator Skill: Proper setup, calibration, tooling selection require training.

-

Related Products

Related products

-

Sale!

Automatic Sipper Heat Press Machine- Sublitech

₹ 16,999Original price was: ₹ 16,999.₹ 8,999Current price is: ₹ 8,999. Add to cart -

Sale!

Large Size Sublimation Printer- Sublitech

₹ 750,000Original price was: ₹ 750,000.₹ 480,000Current price is: ₹ 480,000. Add to cart -

Sale!

Mug Heat Press Machine – Sublitech

₹ 7,999Original price was: ₹ 7,999.₹ 3,500Current price is: ₹ 3,500. Add to cart -

Sale!

Startup Combo: Your All-in-One Printing Solution- Sublitech

₹ 29,999Original price was: ₹ 29,999.₹ 24,500Current price is: ₹ 24,500. Add to cart

Reviews

There are no reviews yet.